Polyethylene Foam

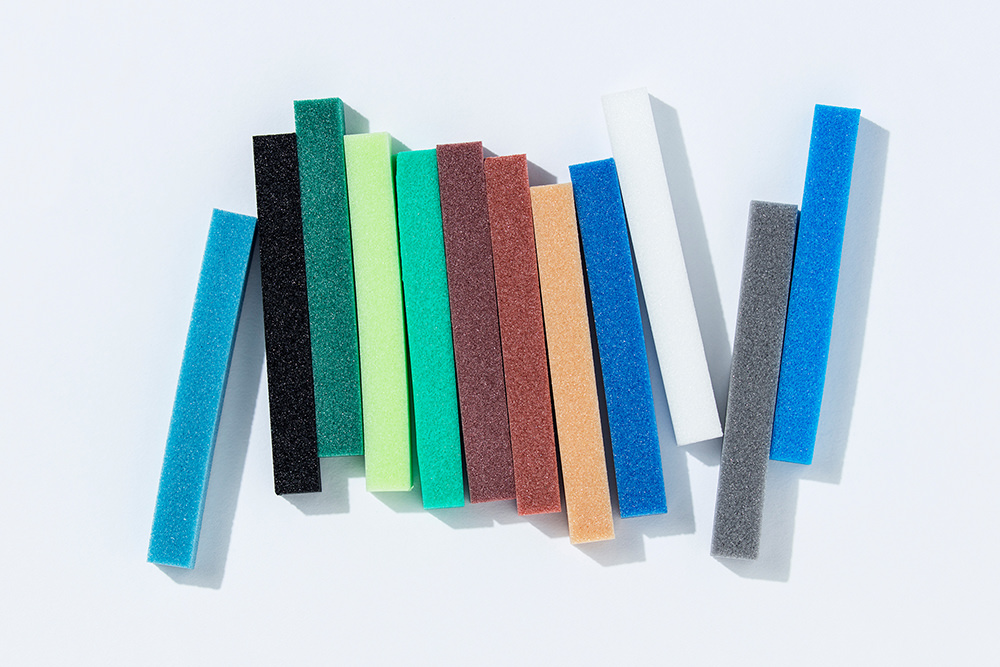

Polyethylene foam used in a variety of products including kickboards and as cushioning in the windows of bullet trains. The foam pieces come in blocks and there are two types- closed-cell foam that does not allow the passage of water and air, and open-cell foam that allows for water and air to pass through. The foam can come in many forms, including different slices and cuts, with holes, and thermo-compressed shapes. It can also be made to hold up acidic medicines, heat, oil, and non-combustible. This time the scraps have been smashed into chips, the surface melted and the pieces pressed into a colorful material.

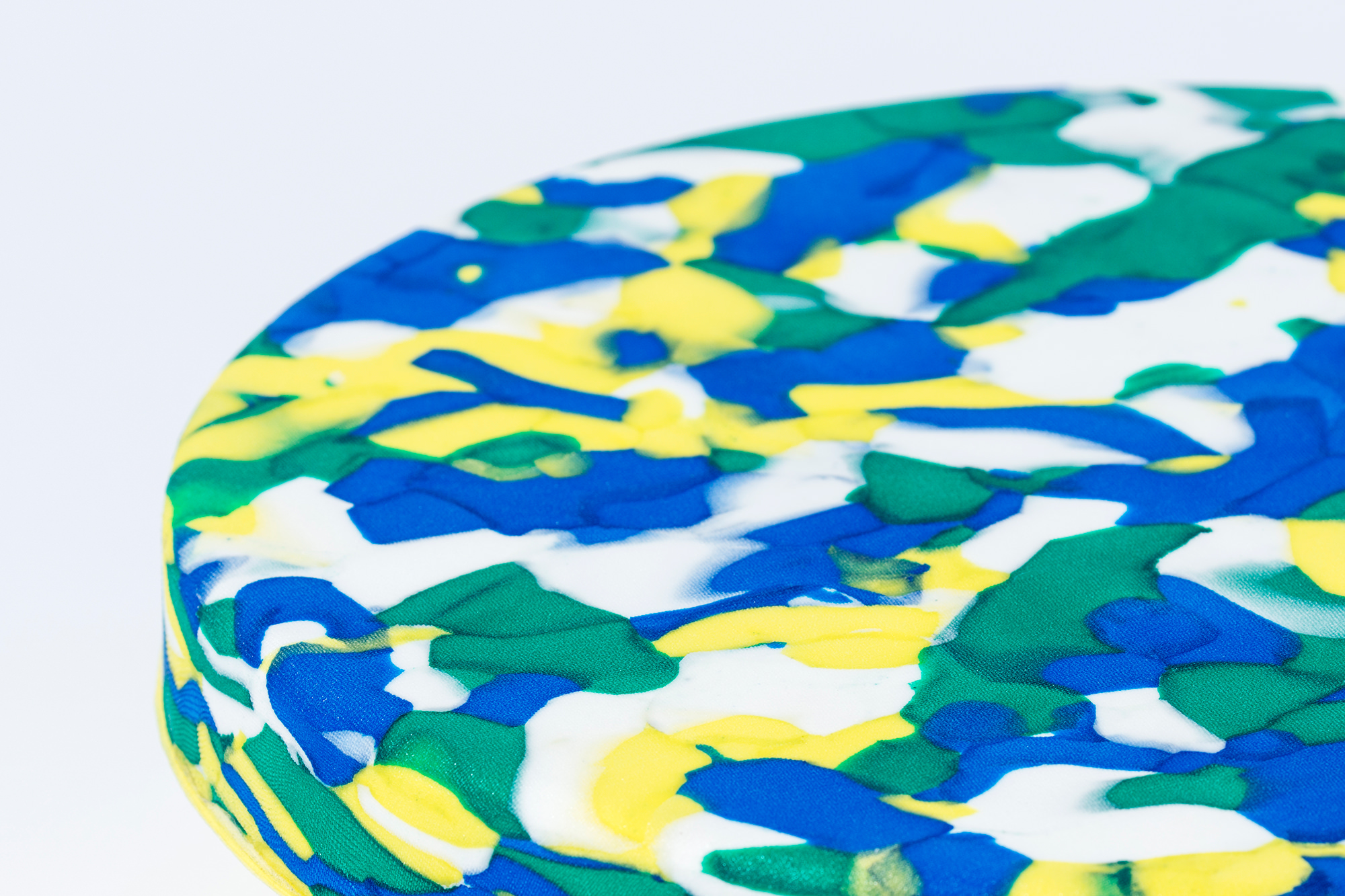

POLYMOCK STOOL

Notice the bright colors and beautiful shapes created by the thermo-compression of these Sunpelca polyethylene foam pieces used in kickboards and as packing material. Each piece is unique as they are made from scraps produced during the thermo-compression process. Using thermo-compression, the pieces were made into a small colorful stool.

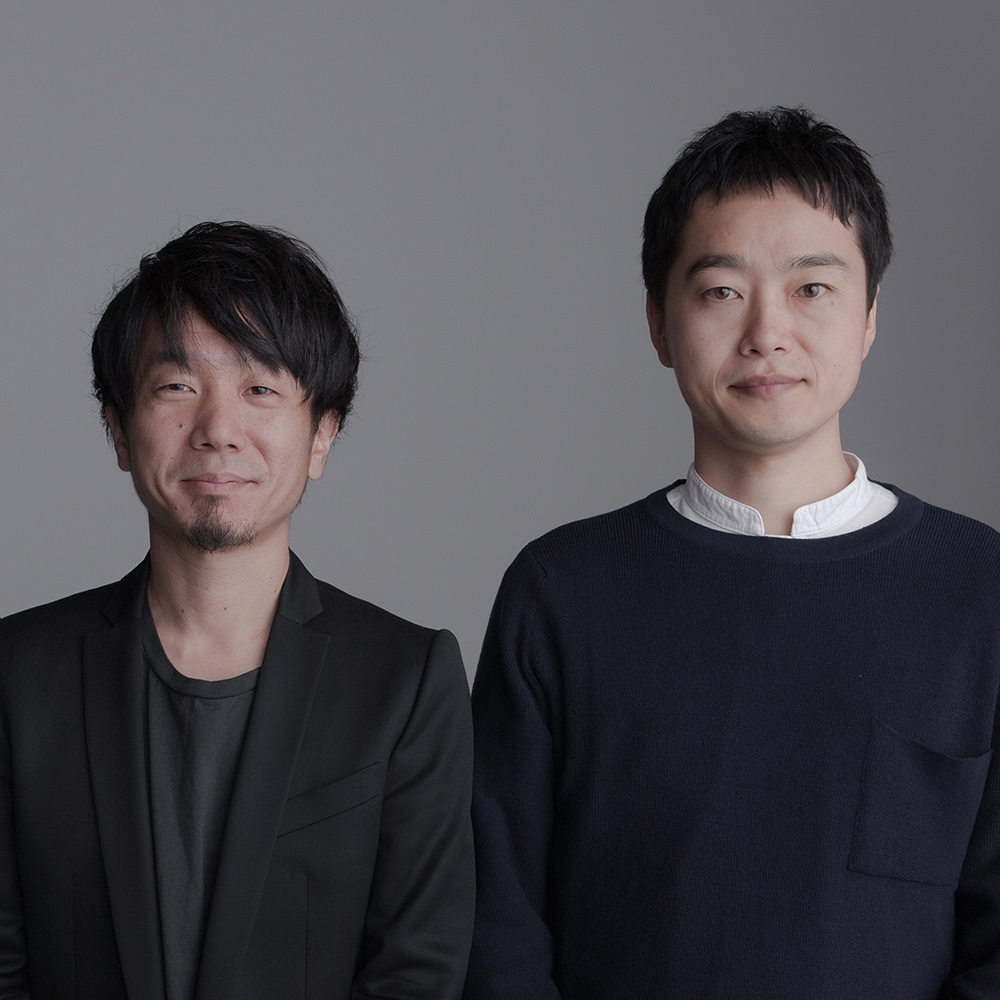

DESIGNER

TORAFU ARCHITECTS

Founded in 2004 by Koichi Suzuno and Shinya Kamuro. Starting with architectural planning, Torafu has brought their architectural thinking to a wide range of fields such as interior design, exhibition spaces, product design, installations, and movie production. Notable projects include Template in Claska, Nike 1Love, Residences in Kohoku, Airvase, Gulliver Table, and Big T. As part of Canon’s Milano Salone 2011 exhibit, they were awarded the Milano Design Award for Light Loom.

In 2015, Airvase became a part of the permanent collection at the Montreal Museum of Fine Arts. In 2011, Torafu published ‘Airvase Book: Torafu Architects 2004-2011’, showcasing the ideas and process behind their work. 2012 saw the publication of the picture book ‘Small-sized Urban Planning by Torafu’, followed by ‘Inside Out: Torafu Architects’ in 2016.

WEBSITE

MATERIAL

Polyethylene Foam

Polyethylene foam used in a variety of products including kickboards and as cushioning in the windows of bullet trains. The foam pieces come in blocks and there are two types- closed-cell foam that does not allow the passage of water and air, and open-cell foam that allows for water and air to pass through. The foam can come in many forms, including different slices and cuts, with holes, and thermo-compressed shapes. It can also be made to hold up acidic medicines, heat, oil, and non-combustible. This time the scraps have been smashed into chips, the surface melted and the pieces pressed into a colorful material.

WEBSITE

SANWA KAKO CO.,LTD.

56 Butsugenji-cho,Kamitoba,Minami-Ku,Kyoto City,Kyoto,601-8103,Japan

http://en.sanwa-chemi.co.jp

Sanwa Kako started in 1965 in Kyoto, Japan as a polyethylene foam maker. For over a half-century the company has focused on technological development, striving to create “form from foam”. In recent years, expanded from developing and producing synthetic rubber to developing adhesive and thermo-compression processes to produce three-dimensional foam products. Sanwa Kako is bringing their imaginative ideas to the exhibition for the second year in a row.

Contact

DepartmentFoam Design Center

StaffMasaaki Sahara

Tel+81-75-671-5188